Introduction

Based on a series of discussions in the period 1990–1992, the international co-operative research project, DECOVALEX, DEmonstration of COupled models and their VALidation against Experiments, was launched in Stockholm, Sweden, for the period of 1992–1995 and managed by the Swedish Nuclear Power Inspectorate (SKI). According to the agreement of the participating parties, including both funding organizations and their research teams, the overall objective of the DECOVALEX project was “to increase the understanding of various thermohydromechanical processes of importance for radionuclide release and transport from a repository to the biosphere and how they could be described by mathematical models”. At that time, modeling and testing the coupled THM processes of geological media commonly used in GDRW (Geological Disposal of Radioactive Wastes) repositories was not a mature field of science and technology. Also, a majority of the funding organizations and their research teams participating the project were concerned with basic theories and the development of computational tools with relatively clear and simplified problems—so that key issues relating to outstanding issues for future research, and therefore the practical objectives, were focused on increasing on the following: developing basic understanding of the coupled THM processes, modeling capacities and tools for THM processes in hard fractured hard rock (since at that time granite was selected as the host rock by Canada, Finland, France, Japan, Sweden, UK, i.e. six out of the nine funding organizations).

The intention was to establish validations against well controlled small scale laboratory experiments, especially rock fracture behavior, and exchange of test data among the funding organizations). This reasoning lead to the definitions of three BMT (Benchmark Test) problems (BMT1–BMT3) and 6 TC (Test Case) problems (TC1–TC6) of small sizes, except that TC6 was an in-situ coupled TM experiment of moderate size. Note that the term Benchmark Test (BMT) is used for the modelling of a hypothetical case example; whereas, the term Test Case (TC) is used for the modelling of a laboratory or in-situ experiment.

Due to the success of the research performed by the research teams and efficient management efforts by Steering Committee and Secretariat, led by SKI, this project, under the name of DECOVALEX, has been extended five times (as at 2014), over more than two decades. The first DECOVALEX project was later named as the DECOVALEX-I project, followed by DECOCALEX II, DECOVALEX III, DECOVALEX-THMC, DECOVALEX-2011 and DECOVALEX-2015.

Tasks

The tasks of the DECOVALEX I project were comprised of three BMTs and six TCs, which were divided into three phases:

- Phase I (1991–1993): BMT1, BMT2 and TC1

- Phase II (1992–1994): BMT3 and TC1:2

- Phase III (1993–1995): TC2, TC3, TC4, TC5 and TC6.

The subjects of the BMTs and TCs were as follows:

- BMT 1: Fractured rock with two orthogonal sets of persistent fractures and a heat source, proposed by ANDRA and CEA/IPSN, France;

- BMT 2: Fractured rock with four discrete fractures and a finite length heat source, proposed by AECL, Canada;

- BMT 3: Fractured rock with a realistic fracture network of 6,580 fractures with data from the Stripa mine, proposed by NIREX, UK;

- TC 1: Laboratory shear-flow test on a rock core sample with a single joint, designed and conducted by NGI, Norway;

- TC 2: Field experiment in fractured rock at Fanay–Augéres mine, France, proposed by CEA/IPSN, France;

- TC 3: Large-scale laboratory experiment of engineered buffer material (Big-Ben experiment), proposed by PNC, Japan;

- TC 4: Laboratory stress flow tests on rock fractures, proposed by STUK and conducted by VTT, Finland;

- TC 5: Laboratory shear-flow experiment of a rock block with a single joint, proposed by NRC, USA and conducted by CNWRA, USA; and

- TC 6: Field experiment of hydraulic injection test on fractures at 356 m depth, proposed by SKI, and conducted at LuTH, Sweden.

Organization

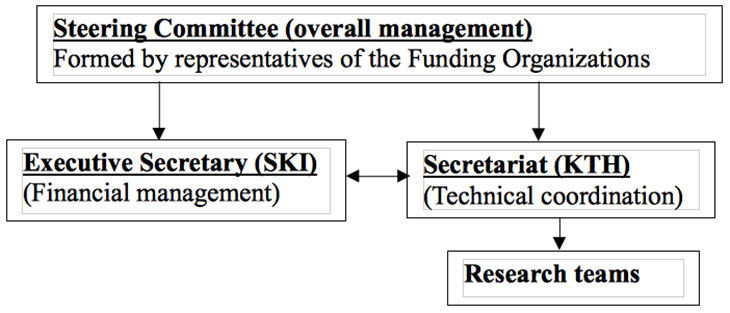

Figure 1 illustrates the organization of the DECOVALEX I project. The Steering Committee was formed by one representative from each Funding Organization, and has the overall power for deciding project aims, contents, tasks, durations, reporting/publications and financing. The Managing Organization (executive secretary) was responsible for managing the project economy and reporting to the Steering Committee meetings about budget and expenditures. The Secretariat was responsible for administrative management of the project, including arrangements of meetings, archives, communications, publications, reporting, and coordinating all tasks (BMTS and TCs). The full names with their acronyms of the funding organizations and research teams are listed in Tables 1 and 2.

| Funding Organization | Acronym |

| National Agency for Radioactive Waste Management, France | ANDRA |

| Commisariat a l’Energi Atomique de Cadarache/ Institute for Protection and Nuclear Safety France | CEA/IPSN |

| Atomic Energy of Canada Ltd., Canada | AECL |

| Power Reactor and Nuclear Fuel Development Corporation, Japan | PNC |

| United Kingdom Nirex Ltd., UK | NIREX |

| Nuclear Regulatory Commission, USA | NRC |

| Swedish Nuclear Fuel and Waste Management Co., Sweden | SKB |

| Swedish Nuclear Power Inspectorate, Sweden | SKI |

| Radiation and Nuclear Safety Authority, Finland | STUK |

(CEA and IPSN formed one FO)

| F.O. | Research team (acronym) | Tasks studied |

| ANDRA | INERIS-LAEGO, Ecole des Mines de Nancy, France, (INERIS); CEA/DMT | BMT1, BMT2, BMT3, TC2 BMT3, TC2 |

| CEA/IPSN | Ecole Nationale Supérieure des Mines de Paris, France, (ENSMP) | BMT1; BMT3, TC2 |

| AECL | AECL, Canada | BMT2; TC1; TC6 |

| AECB | Atomic Energy Control Board, Canada, (AECB), | TC6 |

| PNC | Kyoto University, Hazama Corporation and PNC Tokai Works, Japan, (KPH) | BMT1, TC3 |

| NIREX | AEA Technology, UK, (AEA); Norwegian Geotechnical Institute, Norway, (NGI) | BMT3, TC6 BMT3, TC1 |

| NRC | Center for Nuclear Waste Regulatory Analysis, Southwest Research Institute, Southwest Research Institute, USA, (CNWRA) | BMT2, BMT3, TC1, TC3 |

| SKB | Itasca Geomechanics AB, Sweden, (ITASCA); Clay Technology AB, Sweden, (CLAY); Lund University of Technology, Sweden, (LTH) | BMT3, TC1; TC2, TC3; TC6 |

| SKI | Lawrence Berkeley National Laboratory, USA Royal Institute of Technology, Sweden, (KTH) | BMT2, TC1; TC6 |

| STUK | VTT, Finland | BMT2; BMT3 |

The European Commission (CEC) did not sign the agreement, so that it was not a formal FO but it did act as the funding party for financing the CEA and INERIS teams for modeling BMT1, BMT2 and BMT3.

Besides the nine Funding Organizations, the Steering Committee permitted the Atomic Energy Control Board (AECB), Canada, to act as a participating research team working on TC6.

Products

Four final reports were generated and published by SKI:

- Executive summary for Phases I, II and III, SKI Technical Report 96:58 (Jing et al., 1996),

- Report of Phase I, SKI Technical Report 93:31 (Jing et al., 1993),

- Report of Phase II, SKI Technical Report 94:16 (Jing et al., 1994),

- Report of Phase III, SKI Technical Report 95:80 (Jing et al., 1995).

A book containing 27 contributed chapters from the DECOVALEX project research teams: “Coupled T-H-M processes of Fractured Media”, Stephansson et al., Elsevier 1996;

A special issue of the Int. J. Rock Mech. Min. Sci. Geomech. Abstr., Vol 32, No. 5, 1995 (9 papers, link).

The two papers below are among them, but do not belong to any Tasks.

- L. Jing, C.-F. Tsang, O. Stephansson. DECOVALEX—an international co-operative research project on mathematical models of coupled THM processes for safety analysis of radioactive waste repositories. Int. J. Rock Mech. Min. Sci. & Geomech. Abstr., 1995; 32(5): 389-398.

- G. Rehbinder. Analytical solutions of stationary coupled thermo-hydro-mechanical problems. Int. J. Rock Mech. Min. Sci. & Geomech. Abstr., 1995; 32(5): 453-463.