In the context of radioactive waste geological disposal facilities, a key issue is related to the technical feasibility of the tunnel and shaft seals with respect to their safety functions and their expected performance level. This issue is investigated by IRSN via in situ experiments performed at representative scale, especially focused on quantifying the long-term hydraulic performance. These experiments, which are part of the SEALEX project, constitute the test case which is the object of Task A.

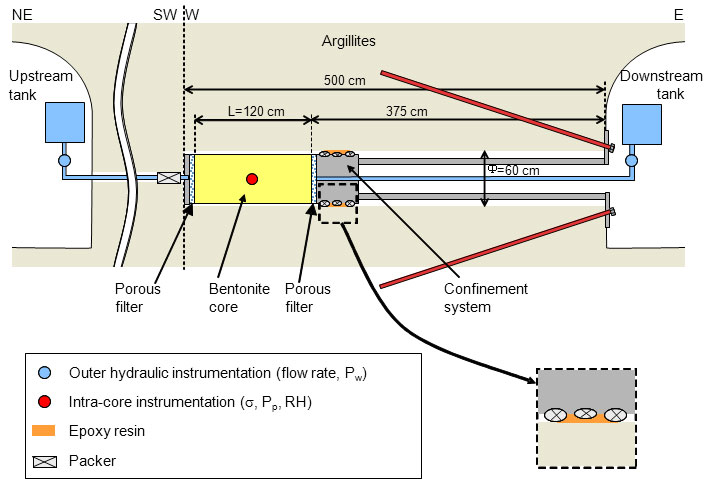

The generic layout of the in situ experiments consists of several components inserted in a horizontal large diameter borehole excavated in the Tournemire argillite:

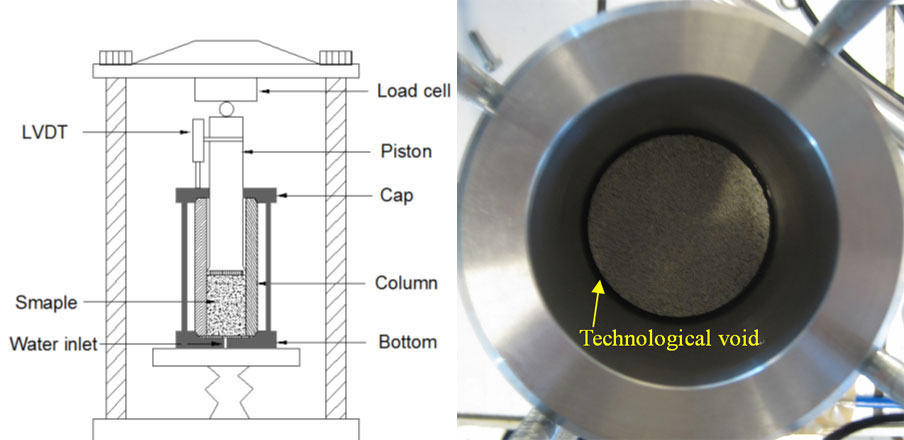

Regarding the test operational phases, water is first pumped into the injection chambers by means of injection lines connected to the injection chambers, which slowly saturates the clay core. At a first stage, it induces a swelling of the clay core, which closes the inner voids of the system (technological voids) and reduces the overall permeability. Then once the voids are filled, a swelling pressure develops due to the constant volume condition, which further reduces permeability.

The bentonite-sand mixture of the swelling core is made of MX80 bentonite (GELCLAY WH2) and quartz sand (TH1000) in dry weight proportions 70/30. Various laboratory tests carried out to investigate the hydro-mechanical behaviour of this bentonite-sand mixture are the following:

A 1/10 scale generic mock-up aims at reproducing the behaviour of the bentonite-sand mixture of the SEALEX experiment, regardless of its interaction with the rock-mass. For this purpose, a compacted sample of bentonite-sand mixture of 120 mm height and 55.5 mm diameter is placed in a rigid (stainless steel) hydration cell of 200 mm length and 60 mm inner diameter, the diameter of which being larger than the sample one in order to simulate the initial technological void which does exist in the in situ SEALEX experiment, between the plug and the surrounding rock-mass. However, contrary to the SEALEX experiment, in the mock-up, the annular void has a uniform thickness. The piston is 60 mm in diameter and 150 mm long. At the bottom side in contact with the soil sample, there is a porous stone of 50 mm diameter with two water inlets (1 mm in diameter). A mechanical press is used to restrain the vertical displacement and a force transducer is used to monitor the swelling pressure. A LVDT fixed on the piston with an accuracy of 0.001 mm allows monitoring the swelling strain when needed. The data (axial pressure and displacement) are recorded automatically to a data logger. The hydration is performed in three phases simulating the evolution of the buffer material upon wetting when considering a technological void.

One in situ test (WT1), used to investigate the hydraulic behaviour of the rock surrounding the bentonite-sand plug, has a purposefully oversimplified design, which considers only the downstream lid with its water tightness system (inflated O-rings and injected epoxy resin), where water mass ‘losses’ resulting from the test outer boundary condition takes place.

Task A is organized in a progressive manner in terms of complexity of the computations to be performed, targeting the full HM understanding of the SEALEX experiment, which is the final objective of this task. To this end, four successive steps are proposed:

For further information, please contact the task leader, Alain Millard (alain.millard@cea.fr) or the SEALEX experimental lead, Nadia Mokni (nadia.mokni@irsn.fr)